Mining solutions - developed with customers and operators for long-lasting operation

Experience, ideas, care and the courage to try out even unconventional solutions  these are our core values.Professional 3D designs, reliable suppliers as our partners and experienced installers  these are our tools.

Successful manufacturers with products that guarantee reliable service with the necessary modification under real conditions  these are what we work with.

Time-honoured conveying machine for mining applications. Although the construction is proven and tested maintenance became too complex and the haul capacity could not be increased.

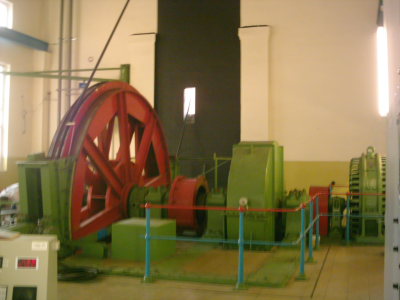

Potash mining. New sheave with integrated direct drive, air-cooled. Drive cooling integrated in the foundation and cooling system for power, control and measurement electronics integrated in the control unit. Developed in cooperation with customer and operator and installed under mining conditions.

A retired sheave. In certain areas the sheave is well-known and a symbol for the industry.

Conveying machine upgrading in potash mining

The high-maintenance drive technology that requires extensive repairs is replaced with direct drives that are integrated in the sheave. The drive cooling is integrated in the foundation and the cooling system for the power electronics is integrated in the control unit. Developed and installed in cooperation with customer and operator. Certainly, the monument protection does not facilitate projects like these.

Full power. Conveyor drive unit in lignite mining. 2x160 kW cooling modules for power electronics on a 35m² roof. Eight cooling circuits provide almost 100% availability.

Delivery to the mining site.

A different kind of vehicle cooling. Bucket-wheel excavators with fully integrated E-container cooling system 3x80 kW based on the N+1 principle with modified serial technology (gray container on top with only the round capacitor air vents visible). This was the prototype. On the bottom right side of the home page you can see another type that currently serves in the Kazakh Steppe.

Conveyor bridge for open brown coal pit in Lausitz: the biggest movable construction sites of the world.

The power electronics of the main drive are also cooled by modified serial technology based on the N+1 principle.

Installing the systems is not the easiest task under these conditions.

Continuous furnace 1995-2009: modules with 35 kW for E-container cooling in mining applications following the N+1 principle.

Modified serial technology fulfils every operator need regarding availability and durability.

Serial production of the 35 kW modules discontinued in 2009.

The challenge: developing and producing a follow-up machine for replacement building and construction of new plant sites without changing the connection points and all that at a competitive price.

This is our solution.

| About us | Info | Imprint | AGB |